It’s time to get behind the scenes and learn a little bit more about what we do at Wine Folly. During the last major press run of posters, we managed to capture a short video on what offset printing looks like and how a poster is made.

Wine Folly’s very first design was “How to Choose Wine”

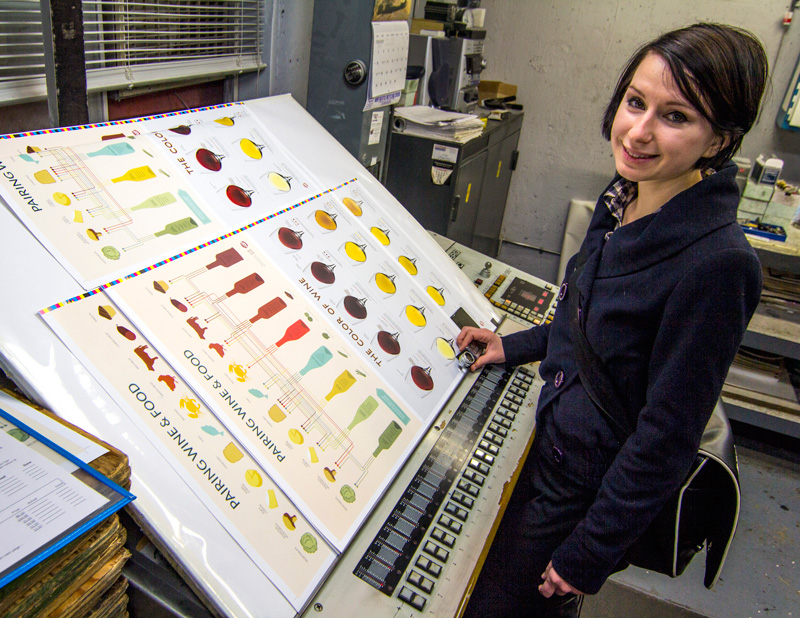

Behind The Scenes: How a Poster is Made

How a Poster is Made

Come Up With A Genius Idea!

For us, the best poster ideas happen in the shower or on a long jog. Your brain needs to feel free to explore. Try turning the lights off when you take a shower. This is Justin’s forte at Wine Folly.

Design a Poster: stay up all night and drink coffee

We design most of our posters in Adobe Illustrator because of its powerful vector imaging and color abilities. For example, take a look at the Wine Color Poster (made in Illustrator!). Madeline Puckettecreates the designs and is inspired by designers all over the world.

Fix Problems: Spelling, Errors, Stress, Whee!

A spelling error in print is the worst thing in the world (for a professional designer). This is the single most stressful thing in making our posters. We take accuracy and truthfulness very seriously so, if you ever catch something, let us know.

Choices: Paper, Ink, and Printing Type

PAPER: Paper choice is a big deal. We use “100lb text” paper which means 500 sheets of industry-standard sized paper weighs 100 lbs (for you international people, that’s 148 gsm). This makes our posters not-too-thick but not-too-thin. We love baby bear paper.

PRINTING: There are three types of printing processes commonly used today: digital, screen print, and offset. Offset printing is the most accurate for color representation but it’s also the most expensive. Screen printing is beautiful and also a touch cheaper if you plan on doing limited edition prints. Digital is something we offer on only short run posters now. The quality there is a bump-up from something you’d find at a FedEx print center.

INK: Ink types vary and soy inks are very common, however light-fast soy inks are not. Light-fast inks are the highest quality inks and will last for hundreds of years in conditions that may receive UV rays. Yes please, sign us up!

Press Run: Lots of Money, Fingers Crossed

During a press run our ultimate goal is that the design looks as good in print as it does on our computer screens. This is harder than it seems because print media uses pigment whereas a computers colors come from light. As a general rule, dark colored designs come out less radiant in the real world than bright and light colored designs.

Our rule is this: “Work with a great printer if you want your work to come out right. Work with an excellent printer if you want your work to come out great.”